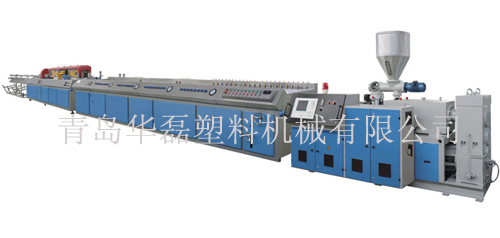

PVC PROFILED MATERIAL PRODUCTION LINE

|

| Characteristics of the equipment |

| YF Series PVC non-profiled material production line is mainly used in PVC door & window profiled material, wide door plate, window plate, extrusion of multi-holes pipe for passing through lines (four holes, six holes, seven holes, nine holes, etc.) For different sectional surface and molds, twin parallel (conical) screws extruder of different specifications can be chosen together with corresponding vacuum calibrating table, haul-off unit, cutting unit, tilter, etc. Capacity of main frame can be optionally chosen from 60-700 kgs/hour. The haul-off unit has applied unique lift technique of our co. Its work is stable, its reliability is good, its pulling force is large. Vacuum setting has applied special enlarged vortex cooling system which is good for cooling and calibrating so as to meet demand of high speed extruding. Movement speed and drawing speed of cutting machine keep synchronous. All movements are controlled by imported PLC, the design is reasonable, the operation is stable, it can conduct automatic cutting with fixed length. Powder & dust suction device can be provided. With different molds, the tilter platform can choose such specifications as 4-meter, 6-meter, 8-meter, 11-meter, etc. With twin parallel screws extruder, it is particularly suitable for high speed extruding of profiled material. | |

|

|

|

Main technical parameter: |

| |

|

Items |

YF180 |

YF240 |

YF300 |

YF600 |

YF900 |

YF1200 |

|

|

180 |

240 |

300 |

600 |

900 |

1200 |

|

|

150 |

150 |

150 |

150 |

150 |

150 |

|

|

2 |

2 |

2 |

30 |

40 |

50 |

|

|

0-5 |

0-5 |

0-5 |

0-3 |

0-2.5 |

0-2.5 |

Auxiliary equipment sum power (kw) |

35 |

35 |

30 |

30 |

40 |

45 |

Cooling water consume (m3/h) |

6 |

6 |

6 |

9 |

12 |

15 |

|

|

0.6 |

0.6 |

0.6 |

0.6 |

0.6 |

0.6 | | | |

|

| Specifications and standard equipment are subject to change without notification. |

|

| |